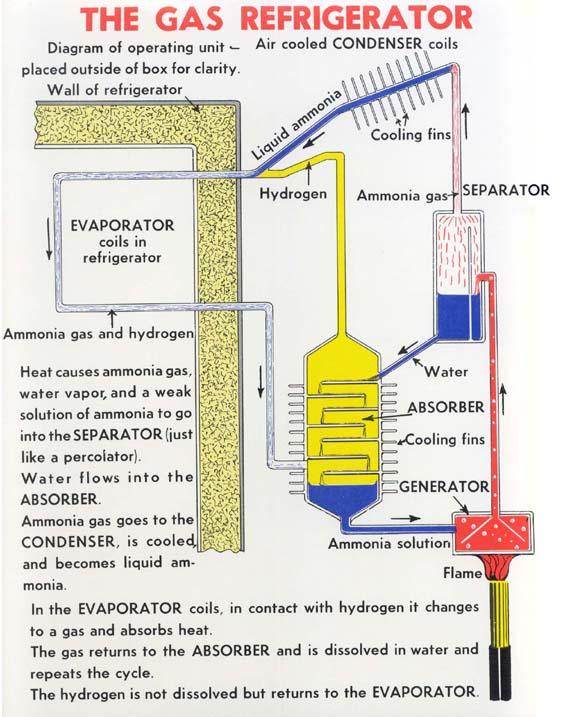

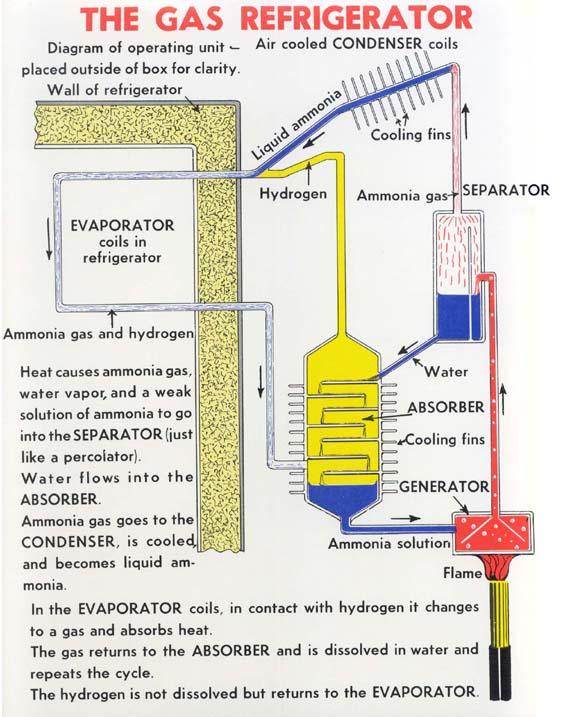

The continuous absorption type

of cooling unit is operated by

the application of a limited

amount of heat furnished by

gas, electricity or kerosene.

No moving parts are employed.

The

unit consists of four main

parts - the boiler, condenser,

evaporator and absorber.

The unit can be

run on either electricity,

kerosene or gas. When the

unit operates on kerosene or

gas the heat is supplied by

a burner which is fitted

underneath the central tube

(A) and when the unit

operates on electricity the

heat is supplied by a

heating element inserted in

the pocket (B).

The unit charge consists of a

quantity of ammonia, water and

hydrogen at a sufficient

pressure to condense ammonia at

the room temperature for which

the unit is designed.

When heat is supplied to the

boiler system, bubbles of

ammonia gas are produced which

rise and carry with them

quantities of weak ammonia

solution through the siphon pump

(C). This weak solution passes

into the tube (D), whilst the

ammonia vapor passes into the

vapor pipe (E) and on to the

water separator. Here any water

vapor is condensed and runs back

into the boiler system leaving

the dry ammonia vapor to pass to

the condenser.

Air circulating over the fins of

the condenser removes heat from

the ammonia vapor to cause it to

condense to liquid ammonia in

which state it flows into the

evaporator.

ANOTHER

VISUAL EXPLANATION -

The evaporator is

supplied with hydrogen. The

hydrogen passes across the

surface of the ammonia and

lowers the ammonia vapor

pressure sufficiently to

allow the liquid ammonia to

evaporate. The evaporation

of the ammonia extracts heat

from the food storage space,

as described above, thereby

lowering the temperature

inside the refrigerator.

The evaporator is

supplied with hydrogen. The

hydrogen passes across the

surface of the ammonia and

lowers the ammonia vapor

pressure sufficiently to

allow the liquid ammonia to

evaporate. The evaporation

of the ammonia extracts heat

from the food storage space,

as described above, thereby

lowering the temperature

inside the refrigerator.

The mixture of ammonia and

hydrogen vapor passes from the

evaporator to the absorber.

Entering the upper portion of

the absorber is a continuous

trickle of weak ammonia solution

fed by gravity from the tube.

This weak solution, flowing down

through the absorber comes into

contact with the mixed ammonia

and hydrogen gases which readily

absorbs the ammonia from the

mixture, leaving the hydrogen

free to rise through the

absorber coil and to return to

the evaporator. The hydrogen

thus circulates continuously

between the absorber and the

evaporator.

The strong ammonia solution

produced in the absorber flows

down to the absorber vessel and

thence to the boiler system,

thus completing the full cycle

of operation.

The liquid circulation of the

unit is purely gravitational.

Heat is generated in the

absorber by the process of

absorption. This heat must be

dissipated into the surrounding

air. Heat must also be

dissipated from the condenser in

order to cool the ammonia vapor

sufficiently for it to liquefy.

Free air circulation is

therefore necessary over the

absorber and condenser.

The whole unit operates by the

heat applied to the boiler system

and it is of paramount importance

that this heat is kept within the

necessary limits and is properly

applied.

![]() 2009-2017

by Todd W. White

2009-2017

by Todd W. White![]()

The evaporator is

supplied with hydrogen. The

hydrogen passes across the

surface of the ammonia and

lowers the ammonia vapor

pressure sufficiently to

allow the liquid ammonia to

evaporate. The evaporation

of the ammonia extracts heat

from the food storage space,

as described above, thereby

lowering the temperature

inside the refrigerator.

The evaporator is

supplied with hydrogen. The

hydrogen passes across the

surface of the ammonia and

lowers the ammonia vapor

pressure sufficiently to

allow the liquid ammonia to

evaporate. The evaporation

of the ammonia extracts heat

from the food storage space,

as described above, thereby

lowering the temperature

inside the refrigerator.